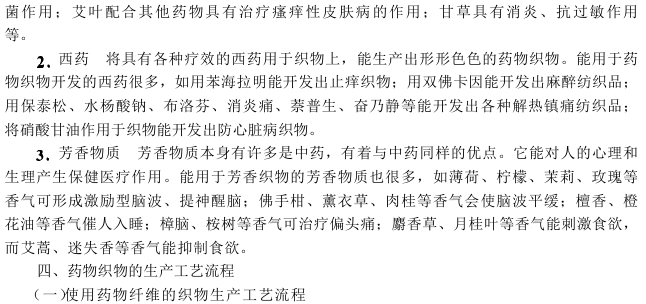

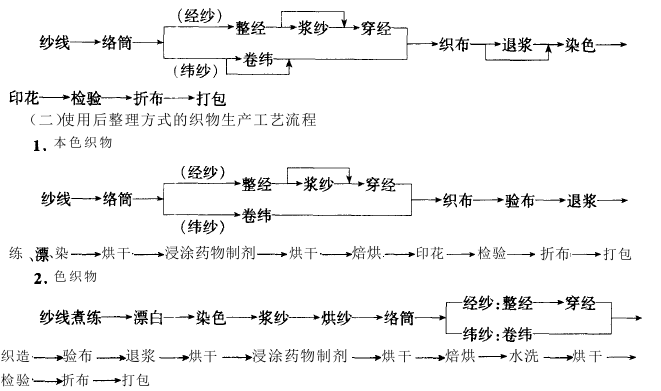

Key points of pharmaceutical fabric design and production process

1. Characteristics and development trends of pharmaceutical fabrics

(1) Characteristics of pharmaceutical fabrics

Pharmaceutical fabrics refer to fiber fabrics with medical functions. It combines drugs and fabric work clothes. At the same time, during the wearing process, the drug ingredients enter the human body through respiration and skin absorption, producing medical and health care effects. Therefore, pharmaceutical fabrics can also be regarded as a new pharmaceutical fabric. Since drug fabrics directly combine drugs and fabric work clothes, this provides the possibility and convenience for local administration and external treatment of internal diseases. It can also improve the effective utilization of drugs.

Use medicinal fabrics to make underwear, bedding, etc., which can apply medicine to a large area for a long time. Conducive to disease treatment.

(2) Development Trend of Medicinal Fabrics

People’s consumption of fabrics has gone far beyond keeping warm. On the premise of being beautiful, they are moving towards the goals of comfort and health. Medicinal fabrics can just meet the requirements of comfort and health. Currently, more and more varieties of pharmaceutical fabrics are being developed. From work clothes (such as underwear, pajamas, pantyhose, etc.) to handkerchiefs, towels, sheets, quilts, mattress wadding and pharmaceutical non-woven fabrics, etc. The variety covers a wide range of areas. Judging from the market situation of pharmaceutical fabrics, its development direction has the following three trends:

(1) Expanding the market. Increase the variety of medicinal fabrics. Expand its quantity and expand its application fields.

(2) Popularity. While ensuring the medicine, we also start from the fabric, style and color of the work clothes to meet their popularity, so that the products will not just become hospital supplies.

(3) Functional integration. It is not only limited to a certain drug function, but while exerting its drug function, it can also be combined with other functions, such as heat preservation, covering, etc.

2. Classification of medicinal fabrics

Medicinal fabrics can be divided into the following three types according to the different drugs used:

(1) Traditional Chinese medicine fabrics

Add the extracted ingredients of traditional Chinese medicine directly to the post-finishing In the formulation, microcapsule technology may be used to contain the active ingredients of traditional Chinese medicine for PU coating, or coloring technology may be used to combine the active ingredients of traditional Chinese medicine into the fibers of the fabric. The fabric has certain medicinal properties.

(2) Western medicine fabrics

Break the Western medicine into fine powder, directly mix it into the spinning solution, and blend the chemical fiber fabrics, or use the microcapsule PU coating method, or connect certain drug groups The branches are attached to the fibers or the modified medicinal dipping method is used to produce western medicinal fabrics.

(3) Aromatic fabrics

Since natural aromatic substances have medical effects such as refreshing, calming and soothing, anti-migraine, suppressing appetite or promoting appetite, they can have psychological and physiological health care effects on people. . Its therapeutic effect is first to adjust the function of the nervous system and influence human brain consciousness, and secondly, the aroma enters the blood circulation and promotes cell metabolism through its pharmacological effects.

3. Pharmaceutical fabric design

(1) Fabric tissue specification design

1. Raw material design According to different uses, natural fibers, man-made fibers and synthetic fibers can be used.

2. Spinning yarn design Spinning yarn can be either single yarn or stranded yarn. The twist is similar to conventional fabrics. The yarn used in the fabric can be pure yarn or blended chemical fiber fabric yarn.

3. Fabric density design The warp and weft density of the fabric can be determined according to the number of spinning yarns used and the purpose of the fabric. The design method is similar to conventional fabrics.

4. Fabric weave design Depending on the purpose of the fabric, the selected fabric weave is also different. For underwear, choose a simple weave; for sheets, you can use a combined weave; for pajamas, you can use a changing weave or a towel weave, etc.

(2) Design of combination method of drugs and fabrics

1. Finishing of drug fibers

(1) Post-finishing method. Almost all pharmaceutical finishing techniques used on fabrics can be used on fibers and yarns. However, during the fiber fabrication process, the drug properties are often lost due to damage to the PU coating. Therefore, this method has great limitations.

(2) Blended chemical fiber fabric silk method. The drugs and aromatics are evenly mixed into the spinning liquid for spinning without changing the traditional spinning equipment. Fiber base materials often use polyester, polyamide, etc.

(3) Core-sheath spinning method. This method directly uses the core-sheath bonding technology that emerged in the 1980s. The sheath uses polyester, polyamide and other fiber materials to maintain fiber properties. Drug substances are added to the core material. In order to prevent the loss of the drug during spinning, the core material is often made of polyethylene copolymers or homopolymers with very low melting points and hydrolysis resistance. The drugs escape along the longitudinal direction of the fiber and exert their medicinal properties. effect. Varieties produced by this method include hollow core-clad types (the core containing aromatic substances is made into a hollow structure, which can enhance the concentration of drugs escaping from both ends) and hollow multi-core core-clad types (the hollow structure is made of multiple cores). material and outer sheath).

(4) Modified impregnation method. Select a certain oil-absorbing polymer to be blended and spun into conventional chemical fibers to modify them, and then immersed in oil-based fragrances and kept under pressure or normal pressure for a certain period of time. The oil-absorbing polymer can absorb enough fragrances. The fiber acquires aromatic properties.

2. Post-finishing technology of pharmaceutical fabrics

(2) General coating and dipping method. Soak the fabric in the finishing liquid, which contains pharmaceutical preparations, adhesives, etc.; you can also add microporous powders such as calcium carbonate to absorb drugs to coat the fabric with PU, and you can also add drugs to the printing surface Printing on fabrics in color paste, etc. The fabrics produced by this method have poor durability.

AAAFGBHGYUTKU