Understanding and suggestions on flame retardant requirements for bundled wires

Keynote: With the widespread promotion and application of flame-retardant cloth wire products, the industry is increasingly paying attention to how to understand and apply bundled flame-retardant requirements in the field of cloth wire products. This article interprets standards and conducts verification tests to focus on bundled flame-retardant cloth wire products. The relevant standard understanding, test data and opinions and suggestions were shared on hot topics such as the scope of application, grade classification and arrangement coverage.

Keywords: wire distribution, bundled flame retardant, verification test

1. Introduction

In recent years, with the increasing emphasis on the flame retardant performance of single-core unsheathed cloth wires (hereinafter referred to as “cloth wires”) in various construction projects, as well as the maturity of relevant domestic manufacturing processes, the improvement of raw material performance and the improvement of flame retardant wire standards Implementation, bundled flame-retardant cloth wire products have been widely promoted and applied, occupying an important share of the cloth wire market.

Currently, the flame retardant properties of bundled flame-retardant cloth wires are based on the GB/T 19666 “General Rules for Flame-Retardant and Fire-Resistant Wires, Cables or Optical Cables” and GB/T 18380 “Burning Test of Electric Cables and Optical Cables under Flame Conditions” series of standards. Add bundled flame retardant test categories (ZA, ZB, ZC, ZD) to the product model for identification. In the current situation, on the one hand, due to the habit of full coverage of models in the cable industry, all categories of bundled flame retardants (ZA, ZB, ZC, ZD) are applied to full-size wire products without distinction, such as Z(A, B,C,D)-BV 450/750V 1.5~400. On the other hand, due to the tendency of common sense to arrange the levels of codes A-B-C-D and the non-metallic content in the test from high to low, a large number of manufacturers, users and technical institutions in the industry have flame retardant Class A that has better performance than (covers) Class B and C Understand the sequence of Category 1 and Category D and apply it to actual quality control.

However, with the large number of applications of bundled flame-retardant cloth wire products and the continuous accumulation of related flame-retardant test data, issues such as the scope of application, grade classification and arrangement coverage of different bundled flame-retardant categories in cloth wire products have been raised in the industry. Questions and reflections are increasing day by day. In order to promote relevant parties to more accurately understand the relevant application requirements of bundled flame-retardant categories in the field of cloth wires, and to guide the R&D, production and quality control of related products, this article will use standard interpretation and verification test analysis to focus on bundled flame-retardant cloth wires. Related questions will be answered and suggestions given.

2. Can the bundled flame retardant (ZA, ZB, ZC, ZD) categories be considered as the level of flame retardant performance?

The GB/T 18380.33~36-2008 standard summarizes the provisions of each flame retardant category as follows:

1. Scope of application

The bundled combustion tests of Class A, B, C and D are all used to evaluate the ability of vertically installed bundled wires, cables or optical cables to inhibit the vertical spread of flames under specified conditions. The difference in applicable assessment situations lies in the volume of non-metallic materials. The contents are: high, medium, low and very low. If they correspond to the laying and installation scenarios: Class A corresponds to a large number of wires installed vertically together, Class B corresponds to a large number of wires installed vertically together, Class C corresponds to a large number of wires installed vertically together, Class D corresponds to a smaller number of wires installed vertically together.

2. Test conditions and qualification determination

Different categories of parts have different test conditions, such as fire supply time, sample arrangement, etc., but in the qualification determination, all categories are: the carbonization range on the sample should not exceed 2.5 m above the bottom edge of the blowtorch.

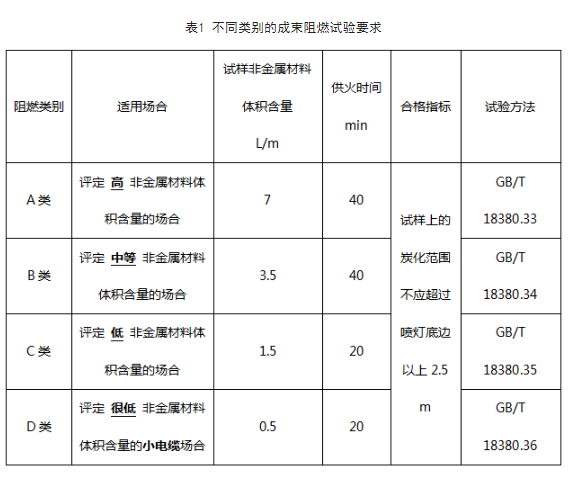

The specific parameter comparison is shown in Table 1.

Table 1 Bundle flame retardant test requirements for different categories

From the above comparison, it can be seen that the relevant standards for bundled flame retardancy do not provide definitions of levels. Instead, categories are used as codes, such as Class A, Class B, Class C and Class D, and there is no clear or implied test for different categories. The high and low levels of product flame retardant performance assessment only indicate that it is applicable to situations with different volume contents of non-metallic materials.

Another analogy is that GB 31247-2014 “Combustion Performance Classification of Electric Cables and Optical Cables”, which is familiar to the cable industry, clearly explains the combustion performance levels specified in the standard. For example, level B1 belongs to flame retardant level 1, and level B2 It belongs to flame retardant level 2. Moreover, unlike the qualification indicators for different flame retardant categories in the GB/T 18380.33~36 standards: “The carbonization range on the sample should not exceed 2.5 m above the bottom edge of the blowtorch”, the B1 level in GB 31247-2014 As different levels from Level B2, there are also significant differences in the setting of judgment indicators.

Summary:

According to the standard analysis, it can be seen that the main difference between the bundled flame retardant (ZA, ZB, ZC, ZD) categories lies in the different applicable assessment occasions, not the level or grade of flame retardant performance, which does not exist in the setting of the standard. High and low level relationships.

3. Are all cloth wire products suitable for bundled flame retardant (ZA, ZB, ZC, ZD) categories?

In the flame retardant test standard for bundled wires and cables GB/T 18380.33~36, in addition to the flame retardant category D, it is clearly stated that it is applicable to “small cables with an outer diameter not exceeding 12 mm and a cross-section not exceeding 35 mm2” (refer to GB/T here) The original text of the IEC 60332-3-25:2018 standard corresponding to 18380.36 has been partially adjusted. The original English text of IEC 60332-3-25 is “This document relates only to small cables of overall diameter 12 mm or smaller and cross-section of 35 mm2 or smaller installed on the test ladder to achieve a nominal total volume of non-metallic material of 0.5 L/m of test sample.”���The validity of bundled flame retardant test results brings risks and challenges. In order to promote the laboratory to more comprehensively grasp the relevant points of flame retardancy of wire and cable bundles, this chapter shares key points of concern and operational suggestions for specific test reference.

a) When some testing institutions have many combustion tasks, after the combustion test of the previous sample is completed, they often start the combustion test of the second sample before the box temperature drops to the ambient temperature. This will seriously affect the second sample. Test results of root samples;

b) Multiple cable samples, especially those with small outer diameters, should be kept vertical after being tied to the ladder frame. If there is an excessive gap between single samples due to bending, the test results will be affected, even seriously. Produce the difference between qualified and unqualified;

c) The air intake method, air intake volume and stability during combustion must meet the standard requirements. In addition, the old-fashioned closed ventilation method at the top of the box will have an impact on the test results;

d) The use of mass flow meters is more conducive to the control of combustion gas and air flow;

e) The distance between the burning surface of the combustion blowtorch and the surface of the sample on the ladder rack will affect the test results;

f) The combustion blowtorch is a consumable item. The air outlet hole on the combustion surface of the blowtorch needs to be cleaned frequently. The blowtorch should be replaced when necessary.

6. Conclusion

Flame retardant performance is an important safety item for wire and cable products, especially in the field of construction wires, where bundled flame-retardant wire products have been widely promoted. At present, in the face of the trend of non-standard application and even “abuse” of flame retardant products in cloth wire products, relevant parties including manufacturing companies, marketing companies, design units, user units and technical institutions, etc., combine the actual characteristics of the products and laying In this scenario, it is particularly important to accurately understand the relevant requirements for bundled flame retardancy of cloth wire products. In this article, the author summarizes and extracts the following views based on standard analysis and verification tests:

1) The main difference between bundled flame retardant (ZA, ZB, ZC, ZD) categories lies in the applicable assessment occasions, not the classification of flame retardant performance. In theory, there is no relationship between high and low levels.

2) For flame-retardant cloth wire products with conductor nominal cross-section greater than 35 mm2, they neither meet the installation requirements for flame-retardant Class A and Class B test samples, nor meet the applicable scope of flame-retardant Class D. Only some specifications can meet the requirements of Flame-retardant C Class test sample installation requirements.

3) For flame-retardant cloth wire products with a conductor nominal cross-section not exceeding 35 mm2, the verification test of multi-bundled combustion Class A~D shows that whether it is a polyvinyl chloride insulated cable or a cross-linked polyolefin insulated cable, its typical small It can be seen from the analysis of the carbonation height of the samples in different flame retardant category tests of the specified products that the flame retardant Class D or C tests are more stringent and representative for this type of small-section cables than the flame retardant Class A and B classes. . In other words, it is risky to use flame-retardant Class A or Class B methods to evaluate a small number of home improvement wires laid and installed. This also brings a hint to cable process design, that is, the oxygen index of the insulation design of flame-retardant Class D or Class C cloth wires should be higher.

Therefore, for the bundled flame retardant test of cloth wire products, when considering related resource constraints and solution optimization, it is recommended to first combine the actual installation and laying scenarios. If there is no specific scenario, priority is given to flame retardant Class D or C for testing. It is worth mentioning that with the standard version change of GB/T 19666-2019, the China Quality Certification Center has correspondingly adjusted the certification scope and sample selection principles in the Flame-Retardant Cloth Wire Certification Implementation Rules (CQC11-463401-2020) optimization adjustments.

This article shares the understanding of relevant standards, test data and opinions and suggestions around the hot spots of bundled flame retardancy in cloth wire products. It will help relevant parties and the user market to understand the application of bundled flame retardancy in cloth wire products more scientifically and objectively. It has important reference value and guiding significance for relevant units to further improve the research and development, production, quality improvement and quality control of flame-retardant cloth wire products.