Research progress on aramid nanofibers and their composite materials

Research progress of Aramid nanofibers and their composite materials

In the late 1960s, aramid fiber (full name “aromatic polyamide fiber”) was first commercialized by DuPont in the United States (trade name Nomex®). It has low density, high modulus, high flame retardancy, and high insulation. , good temperature resistance and other characteristics, it has extensive research and application in the fields of lightweight structures, high temperature protection, and electrical insulation materials. In China, commercial aramid fibers are often named differently between meta-aramid fiber (aramid fiber 1313) and para-aramid fiber (aramid fiber 1414) according to the different positions of the benzene ring connected to the aramid fiber amide group. By processing aramid fibers or aramid liquid crystals through technical means, the diameter can reach tens to hundreds of nanometers and the length can reach several to tens of microns. This kind of fiber is called nano-aramid fiber or aramid nanofiber ( ANFs). The chemical composition, chemical structure and crystal structure of aramid nanofibers are no different from aramid fibers, but their larger specific surface area and aspect ratio allow aramid nanofibers to be composited with other polymers and inorganic materials.

The molecular chains of aramid fiber are connected by amide bonds. The presence of a high proportion of benzene ring structures in the molecules makes the molecules more rigid and has a higher modulus. Therefore, it can be used as both a matrix material and a reinforcing phase component in composite materials. Aramid nanofibers can be prepared by electrospinning, chemical polymerization and chemical pyrolysis. Aramid nanofibers prepared by different methods have differences in fiber aspect ratio and surface activity. Among them, the chemical pyrolysis method has the characteristics of simple operation, high preparation efficiency and low cost, and is a commonly used method for preparing aramid nanofibers.

1

Preparation of aramid nanofibers

1.1 Electrospinning method

The electrospinning method is versatile, flexible and convenient. It is a commonly used nanomaterial preparation technology in cutting-edge fields. Its principle is that after the polymer liquid crystal or melt is charged, it is given a certain amount of electricity under the action of an electric field of thousands or even tens of thousands of volts. The acceleration is stretched to form small jet-like streams that solidify into shape. Therefore, electrospinning technology is greatly affected by equipment, concentration, temperature, solution surface tension, conductivity, etc.

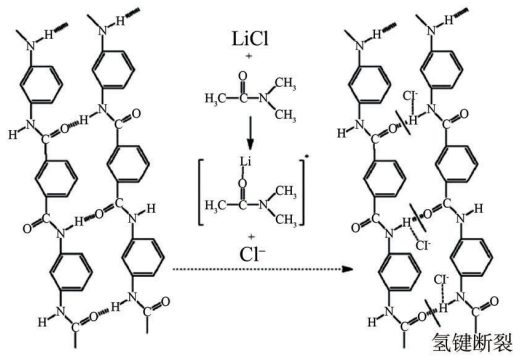

The new electrospinning technology was reported in 2009. Later, Yao et al. used this technology to synthesize dimethylacetamide, dimethylformamide, dimethyl sulfoxide, N-methylpyrrolidone and chloride salts (lithium chloride, (calcium chloride) combined system, meta-aramid nanofibers with a diameter of 100~500nm were prepared; experimental results show that in these systems, the low surface tension, high boiling point, and low vapor pressure of dimethylformamide will cause The rapid evaporation of the solvent is not conducive to the preparation of aramid nanofibers; however, the meta-aramid nanofibers prepared using lithium fluoride/dimethylformamide have better morphology; experiments also found that in lithium chloride/dimethylformamide In the system, when the mass fraction of aramid nanofibers is 11% (spinning solution concentration), the prepared aramid nanofibers have the best mechanical properties.

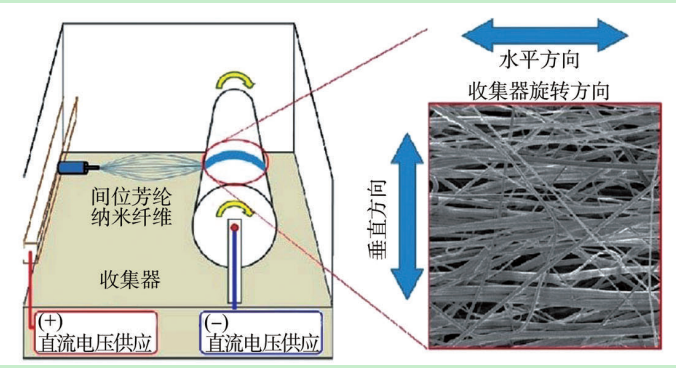

Schematic diagram of preparing aramid nanofibers by electrospinning method

Yeol et al. proposed using a lithium chloride/dimethylformamide system to prepare meta-aramid nanofibers (see Figure 1). Water washing treatment can improve the mechanical properties of aramid nanofibers.

In order to explore the impact of the electrospinning preparation process on the properties of aramid nanofibers, Kang Weimin et al. explored the effects of spinning solution concentration, spinning voltage, extrusion rate and receiving distance on the properties of aramid nanofibers; the results showed that when aramid nanofibers When the mass fraction of aramid nanofibers is 14% (spinning solution concentration), the voltage is 25kV, the extrusion rate is 0.2mL/h, and the receiving distance is 16cm, the prepared aramid nanofibers have the best performance.

Through experimental research, it was found that when preparing aramid nanofibers by electrospinning, the order of factors affecting the diameter of the finished product is: lithium chloride concentration > spinning solution concentration > receiving distance > electrostatic voltage.

Trexler et al. studied the effects of electrospinning environmental parameters on the preparation of para-aramid nanofibers and the strength of para-aramid nanofiber mats. The results showed that moisture is the key to promoting the formation of hydrogen bonds between molecular chains of aramid nanofibers. Electrospinning Controlling humidity during the spinning process can effectively regulate the strength of aramid nanofiber mat.

1.2 Chemical polymerization method

Chemical polymerization method (also known as surfactant method and bottom-up preparation method) is a preparation method that controls the size of aramid nanofibers by controlling the polymerization reaction process. Specifically, an end-capping agent is added to the polymerization reaction system. When the molecular chain of the aramid fiber grows to a certain extent, the end-capping agent can inhibit the polymerization reaction, thereby preparing aramid nanofibers.

Schematic diagram and characterization diagram of preparation of aramid nanofibers by chemical polymerization method

material

Aramid nanofiber material has strong environmental adaptability, is lightweight, non-toxic and easy to mold. It is an ideal material for the polymer matrix of various electronic products. Luo et al. composited aramid nanofibers with polyaniline to prepare an all-polymer lightweight electromagnetic shielding material; the results showed that the composite material had a tensile strength of 179MPa, a shielding efficiency of 30dB, and excellent overall performance.

Xie et al. composited aramid nanofibers with the lamellar nanomaterial MXene to prepare ultra-thin aramid nanofiber electromagnetic shielding materials. The results showed that the conductivity of the composite material was 1.7S/m. When the material thickness was 20 μm, Its shielding efficiency is 28dB (8.2~12.4GHz range). Hu et al. prepared an aramid nanofiber/carbon nanotube airgel composite with a porous structure through freeze-drying; the results showed that the composite had a specific surface area of 232.8m2/g, a conductivity of 230S/m, and a shielding efficiency of 54.4 dB.

2.6 Thermal insulation materials and electric heating materials

Preparation of aramid nanofiber thermal insulation airgel

Based on the insulation and low thermal conductivity characteristics of aramid nanofibers, Luo et al. prepared aramid nanofiber aerogels through a directional freeze-drying method; the results showed that the thermal conductivity of the material was 0.036W/(m·K), and the infrared emissivity was 0.94, which is expected to be used in the fields of heat insulation and infrared stealth. Xie et al. prepared aramid nanofiber thermal insulation aerogel with a layered structure through monomer polymerization and freeze-drying (see Figure 6), with a thermal conductivity of 0.0372W/(m·K). Li et al. prepared a composite aerogel with thermal insulation and insulation properties by combining aramid nanofibers and silica, with a thermal conductivity of 0.0221W/(m·K). Young et al. introduced multi-walled carbon nanotubes into aramid nanofiber matrix to prepare a rapid electric heating material; the results show that the electroosmosis threshold of the three-dimensional conductive network constructed by multi-walled carbon nanotubes and aramid nanofibers is 0.085wt% multi-walled Carbon nanotubes have a resistance control range of 1~108Ω·cm. At the same time, because this material does not emit electromagnetic waves harmful to the human body during electric heating and has a fast response speed, it can be used for floor heating, mirror or window glass defrosting, oil or solution heating, etc. . Ma et al. prepared an electrically heated fast-response material by embedding silver nanowires into an aramid nanofiber membrane. The maximum heating temperature of the material can reach 200°C.