Carbon fiber + aramid + ultra-high molecular weight polyethylene! We want to build a “fiber capital” here

Carbon fiber + aramid + ultra-high molecular weight polyethylene! We want to build a “fiber capital” here

1

development Goals

By 2025, the construction of an international “fiber capital” will be fully launched and the fiber industry ecology will be basically improved. The ecosystem of fiber industry R&D, production, application and services will be more complete, and the industry scale of the fiber ecosystem will reach 5 billion yuan;

By 2030, a national fiber materials industry cluster will be basically established, and significant progress will be made in high-end breakthroughs in the fiber industry. The field of high-strength fiber industry has accelerated its growth, and traditional fibers have made effective breakthroughs in the high-tech and high-end transformation, forming an advanced industrial form and professional division of labor pattern dominated by high-strength fiber and integrating development of fiber manufacturing and fiber services;

By 2035, the international “fiber capital” will be basically built and a world-class fiber industry cluster landmark brand will be formed.

2

Development focus

Gradient development of three high-strength fibers.

Carbon fiber focuses on scale improvement, accelerating the industrialization of low-cost large tow carbon fiber and composite materials, strengthening the supply of resins, sizing agents and other supporting facilities, and accelerating the coordinated development of “high performance + universal” and “large tow + small tow”.

Aramid fiber focuses on industrial development, accelerating the introduction of high-strength, high-elongation meta-aramid industrialization technology, accelerating the development of 10,000-ton aramid polymer monomer breakthrough capabilities, and accelerating import substitution in product applications.

Focus on the implementation of ultra-high molecular weight polyethylene fiber projects, expand the 10,000-ton scale test production of M5 million ultra-high molecular weight polyethylene, develop ultra-high molecular weight polyethylene pipes, profiles, special materials for polyolefin lithium battery separators, etc., and increase industrial agglomeration.

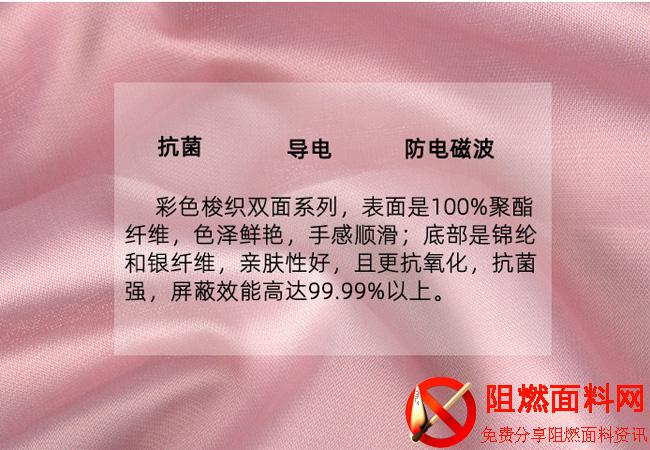

Accelerate the development of emerging fibers. Prospectively develop the “species evolution” of fiber materials, vigorously develop multi-shaped, multi-color, and multi-dimensional fibers, and accelerate the development of high-performance fiber composite materials such as “fiber + metal”, “fiber + ceramic”, and “fiber + carbon material”. Promote the development of general fiber fields such as polyester fiber, nylon fiber, and polyester fiber, and create functional, differentiated, and green fiber varieties such as flame-retardant fiber, hollow fiber, and green fiber.

Collaboratively develop fiber equipment.

Vigorously develop the producer service industry.

3

development tasks

Accelerate the realization of the production capacity of carbon fiber large tows to exceed 10,000 tons, the production capacity of ultra-high molecular weight polyethylene resin to reach 10,000 tons, strive for a breakthrough of 10,000 tons of aramid application demand, and strive for the city’s production capacity of ultra-high molecular weight polyethylene fibers, raw materials, etc. Optimize the layout and accelerate the improvement of regional fiber industry agglomeration level.

Accelerate the research and development and pilot testing of carbon fiber raw materials, structural design andSimulation, parts batch manufacturing and verification, composite material testing and certification, composite material standards and information platform, incubation acceleration and industrialization and other functional platform construction, jointly build a national carbon fiber composite innovation center.

Strengthen market penetration of fiber materials, focus on the opportunities for substitution and upgrading of traditional materials in emerging fields such as aerospace, rail transit, hydrogen energy, and marine engineering, and accelerate the research and development and production of integrated shell materials, lightweight materials, carbon fibers for hydrogen storage bottles, and high-efficiency flame-retardant fibers and other high-end fiber products, focusing on mature application fields such as biomedicine, sports and leisure, pressure vessels, power and electrical. Research and develop extreme high-temperature fiber materials such as ceramic matrix composites and carbon-carbon composite materials, extreme low-temperature fiber materials such as corrosion-resistant insulating materials and optical fiber reinforcement materials, ultra-fine aperture special materials for lithium battery separators, and creep-resistant high-end fiber products. materials, breaking through the engineering and industrialization bottlenecks in the extreme application of fiber materials.